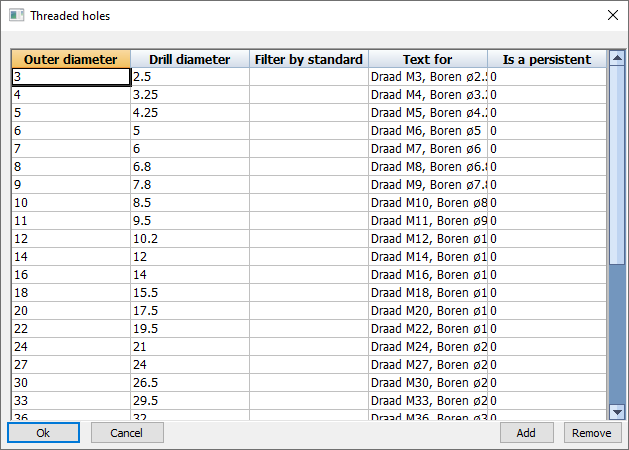

Threaded Holes

In this dialog box you can determine which drill diameter the shop drawings should use for threaded holes. For illustration purpose threaded holes have some extra lines in 3D similarly to the thread of a real hole.

If you convert a regular hole into a threaded hole, the diameter of that hole will be set to match the diameter of the bolt.

Here you can adjust for each threaded hole diameter the drill diameter that the annotation on the shop drawing should contain.

By default the annotation of a threaded hole will look like this : Drill ø10.2 Tap M12

The annotations in workshop drawings that contain the variable %PbColCommentForHoleDriller% will contain this string.

Parabuild uses the first 2 columns to compose this string.

The column Text for annotations is a separate string that will be used instead of the above string, but only if the last column Is a persistent override is active for the row.

The column Filter by standard applies an extra filter for the entire row. Just enter the standard of the bolt here, and the row will only be applied to those bolt standards.

Thanks to this we filter can create multiple rows for the same diameter, but with different drill diameters. This is useful when different tapping tools are used in the same 3D drawing.

A threaded hole is different from a regular hole, even when Parabuild numbers your elements.

If there are 2 identical plates with the same number of holes at the same location, but one plate has one of its holes threaded and the other does not, Parabuild would assign these two plates a different position number.