Bolt Assemblies

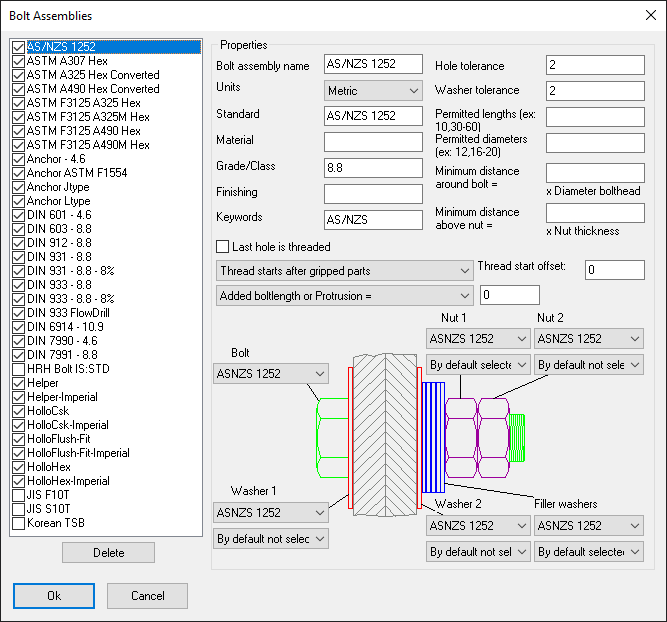

The assembly of a bolt determines the standards of the bolt, washers and nuts. We can also determine the default tolerance of the holes in the assembly.

A summary of all existing assemblies is shown in the top left-hand side of the dialog window. Clicking on one of the assemblies will display all of its settings. These settings can be changed on the directly. Activating another assembly will save all the changes that you made to the current assembly. If another assembly name is assigned to the assembly then a new assembly with that name will be created.

The standards of the bolts, nuts and washers that are presented in the dropdown boxes are retrieved directly from the Bolt parts database.

With the nuts and washers a selection may be made between not, yes, never or always. When you choose yes or not, you effectively determine whether a new bolt drawn in 3D will have the nuts/washers enabled/disabled by default. When you choose always or never, you will not be able to disable/enable them after drawing the bolt.

The added length can be made diameter dependent. The added length is to make the bolt longer than is actually necessary. A good example of this is the anchor bolt: which only needs to pass through a footplate, but must actually be much longer.

The added length and the hole-tolerance can still be changed after the bolt was drawn.

The settings Permitted lengths and Permitted diameters are useful quick filters. As the bolt standard contains many bolt diameters and lengths, but in practice most of these bolts are not used. The diameters and lengths that you enter here should match the bolts that the erectors bring to the site. This way, the Parabuild bolts list will accurately match the bolts that the erectors will need on site.

This is the sequence that Parabuild uses when a new bolt is drawn :

- Parabuild searches within the selected assembly for the standard for the new bolt, washers and nuts that should be used.

- Using this standard, Parabuild refers to the bolt parts database and selects a bolt using the following details: Standard, diameter and length (length = penetration length + washers + nuts + added length).

- Only the bolt parts that fall within the above Permitted lengths and Permitted diameters filters are used by Parabuild

The Thread start type option offers the following choices :

- Thread starts anywhere - This is typically used for standards with full threads

- Thread starts after shear plane - The bolt length will be changed to make sure that the thread does not pass through the shear plane. See below for more information about the shear plane.

- Thread starts after shear plane (ignore runout) - Same as above, but the runout distance is ignored. The runout is calculated based on the diameter of the bolt (see table below)

- Thread starts after gripped parts - The bolt length will be changed to make sure that the thread does not pass through gripped parts. See below for more information about the gripped parts plane.

- Thread starts after gripped parts (ignore runout) - Same as above, but the runout distance is ignored. The runout is calculated based on the diameter of the bolt (see table below)

Thread start offset - This option works in conjunction with the thread start option : Enter an additional offset to be added to the thread length of the bolt.

The runout is the transition area between the thread and the shank.

The runout is calculated based on the diameter of the bolt using the following rules :

Metric runout rules |

Imperial runout rules |

|||

Diameter |

Runout (mm) |

Diameter |

Runout (inches) |

|

<= 4 |

1.5 |

<= 1/2 |

0.19 |

|

<= 7 |

2.5 |

<= 5/8 |

0.22 |

|

<= 12 |

4.0 |

<= 3/4 |

0.25 |

|

<= 16 |

5.0 |

<= 7/8 |

0.28 |

|

<= 22 |

6.0 |

<= 1 |

0.31 |

|

<= 27 |

7.0 |

<= 9/8 |

0.34 |

|

<= 33 |

8.0 |

<= 10/8 |

0.38 |

|

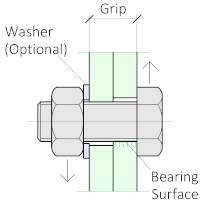

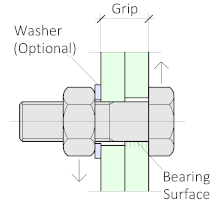

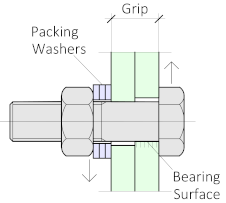

To further explain these options, consider the following 3 situations of the position of the bolt shank and thread relative to the shear plane or gripped parts :

|

|

|

Thread starts anywhere, it passes through the shear plane in this case |

Thread starts after the shear plane |

Thread starts after the gripped parts |

The first situation occurs with certain fully threaded standards such as DIN933, but usually also when bolts are > M16 and their length is <= 45.

The second situation is the most commonly preferred; namely where the thread of the bolt does not pass through the shear plane.

The third and last situation is where the thread does not pass through the gripped parts. Filler washers will be needed to make sure that the nut can be tightened, as the thread runout will be positioned outside of the gripped material.

Filler washers can be enabled by default in the bolt assembly, and also individually per bolt in the properties. When enabled, Parabuild will automatically calculate the number of filler washers that are needed.