ISO Weld Symbol

The Basic ISO Weld Symbol

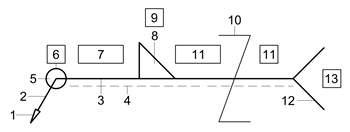

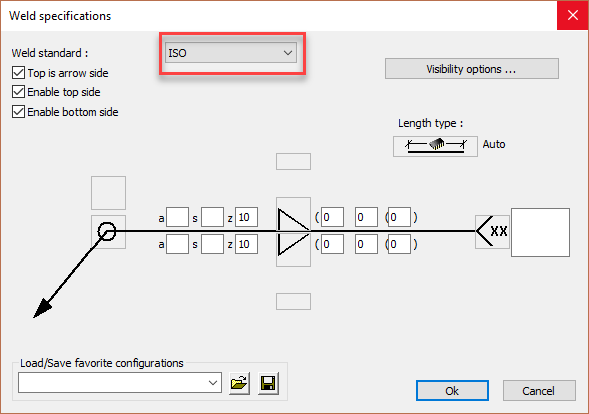

The diagram below illustrates the various elements making up the weld symbol

|

|

Note! * = Fillet welds only ** = Intermittent welds only |

Note: Weld symbols on the full reference line relates to welds on the arrow side of the plate being welded. Weld symbols on the dashed line relates to weld on the far side of the plate. If the welds are symmetrical on both sides of the plate the dashed line is omitted. If the dashed line is below the full line then the symbol for the arrow weld is drawn above the reference line and the symbol for the far side weld is below the dashed line.

The following illustrations clarify this :

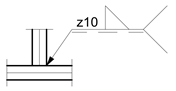

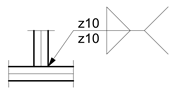

Continuous Fillet Weld - Arrow Side |

||

|

|

|

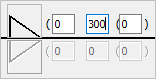

Dialog Setting |

Weld |

Weld Symbol |

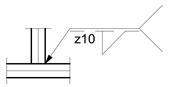

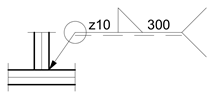

Continuous Fillet Weld - Far Side |

||

|

|

|

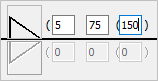

Dialog Setting |

Weld |

Weld Symbol |

Continuous Fillet Weld - Both Sides |

||

|

|

|

Dialog Setting |

Weld |

Weld Symbol |

Editing the Parabuild ISO Weld Dialog

- The Arrow is at the point of the mouse pointer and should be placed at the weld position

- The Leader will stretch in compliance with the movement of the mouse pointer

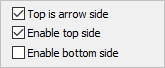

- The Reference line contains all the weld information for the weld on the near side of the plate being welded

- The Dashed line contains all the weld information for the weld on the far side of the plate being welded

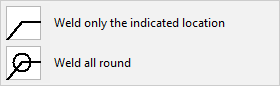

- The Weld type is to indicate whether the weld is to be only at the indicated position or all-round - select either from the dialog

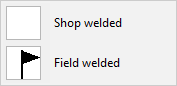

- Shop or Field weld - select either from the dialog

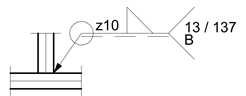

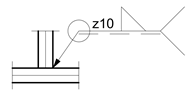

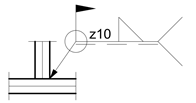

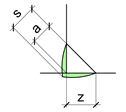

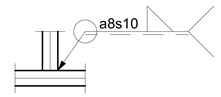

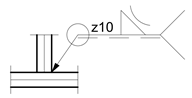

- Weld size - With the ISO system, the weld size is placed to the left of the weld symbol and is preceded by the letters: (z) / (a) / or (z) - depending on whether the leg length or throat thickness is to be specified. Unless otherwise instructed, it is usually the leg length that is specified, in which case only the (z) box needs to be added. If the throat thickness is to be specified, only the (a) box needs to be added.

(s) refers to the effective throat thickness for deep penetration welds and is placed in front of the throat thickness dimension (a) - therefore, if the effective throat thickness (s) is to be specified, both (a) and (s) boxes need to be added

z = Leg Length a = Throat thickness s = Effective throat thickness - for deep penetration welds |

- Weld Symbol - Available weld symbols may be chosen from the list

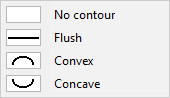

- Weld face contour - select from the dialog

- Intermittent staggered weld symbol - this will be added automatically when the Staggered option is activated in the Length type drop-down options menu

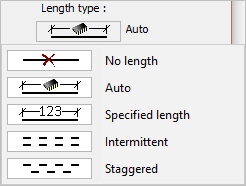

Notes on the length type drop-down

a. No length - No specified weld length

b. Auto - Weld length assumed to be full length

c. Specified length - enter the specified length in the weld length box (See Number, Length, and Spacing of weld elements)

|

|

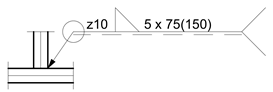

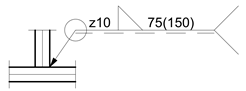

d. Intermittent - Enter the number of welds, weld length, and the spacing of the intermittent weld (See Number, Length, and Spacing of weld elements)

If the number of welds are either not known, or not necessary, simply leave blank, or enter a value of zero

|

|

|

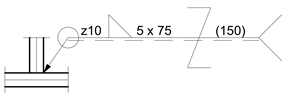

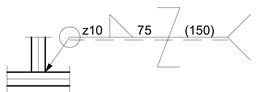

e. Staggered - As with Intermittent welds, enter the number of welds, weld length, and the spacing of the intermittent weld (See Number, Length, and Spacing of weld elements)

If the number of welds are either not known, or not necessary, simply leave blank, or enter a value of zero

|

|

|

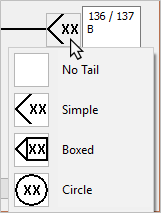

11. Tail - In the tail, ISO recommends placing the welding process reference and the weld class.

The welding process refers to the manner in which the weld, (e.g. Arc welding / ERW welding etc.) is to be placed and are in the form of a numeric code as specified by EN ISO 4063.

The Weld Class refers to the quality of the weld which are designated B / C / and D.

(For a list of codes and classes refer to the ISO website, or Parabuild's Practical Steel Construction web resource.