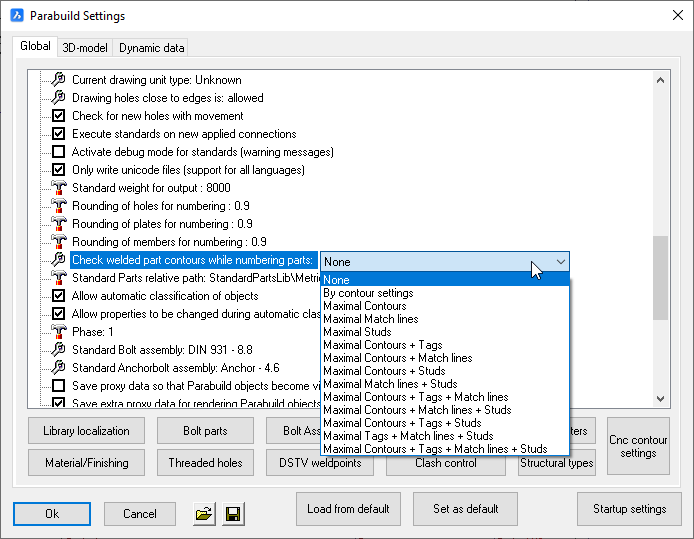

Check CNC contours when numbering parts

This option can be accessed from the Parabuild Global settings.

There are a number of available options, each of them adding more or less contour and matchline data to the numbering.

When contours and/or matchlines are checked while numbering, then the location of a part relative to the attached parts in that assembly may influence its part number.

When tags are added to the numbering, then the part number of each attached part is also considered by the numbering and may also cause a different part number if it differs.

The advantages of enabling this option are :

- Less complexity in the naming of DSTV and DXF files, because the part number will not have to be combined with the assembly number anymore.

- The assembly numbers will not have to be scribed on the part in order to uniquely identify the part.

- There is less potential for confusion when each part with different scribing has a different part number

- Some MIS/MRP/ERP solutions do not support the combination of the part number and assembly number for the CNC files. This issue can be avoided by enabling this option.

One minor disadvantage of this option is that it may result in more part numbers and thus more shop drawings for single parts. The amount of assembly numbers/drawings will remain the same.

Parabuild ensures you will get different NC files (DXF & DSTV) for parts with different contours, whether the option to consider contours in numbering is enabled or not.

When the contour/matchline is not checked during numbering, then Parabuild will add the assembly number to the NC file, but only if necessary.

This is important because if detailing software generates only a single file for parts that may have different contours, this can result in loss of material and errors on the shop floor if the situation is not discovered before welding.

The following illustrations show the difference in numbering when the contours in numbering are activated or deactivated. This example mentions DSTV filenames, but the same goes for DXF.

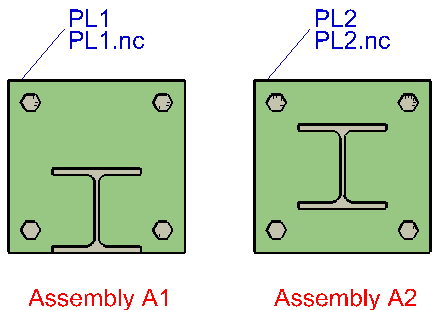

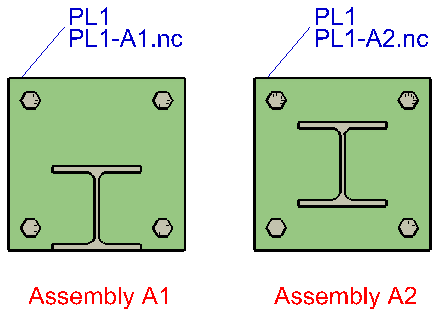

Baseplate and column with checking contours in numbering enabled: the baseplates are equal but have different scribing so they get a different number and a simple NC file name

Baseplate and column without checking contours in numbering: the parts are equal and get the same number. Because the scribing differs, the assembly number is included in the NC filename and will be scribed on the baseplates

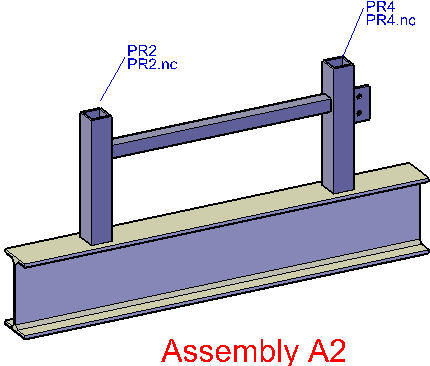

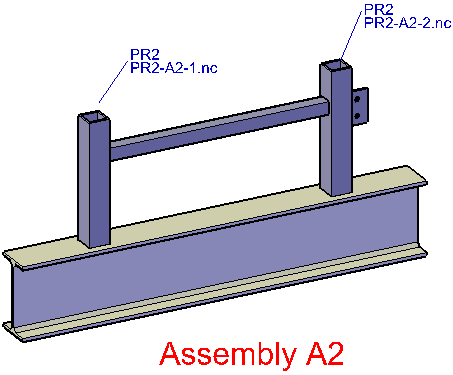

Assembly with checking contours in numbering enabled: two attached parts in the same assembly have the same geometry but different scribing so get a different number and simple NC filename

Assembly without checking contours in numbering: the geometry of both parts is equal so they get the same number. Because the scribing differs, the assembly number and an additional incremental number is included in the NC filename and will be scribed on the attached parts. The additional assembly- and incremental number are only used when needed to uniquely identify two equal-number parts with different scribing.