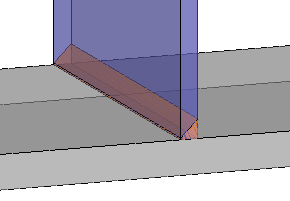

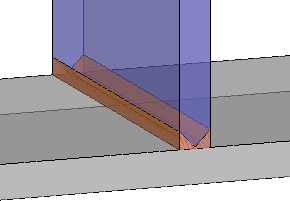

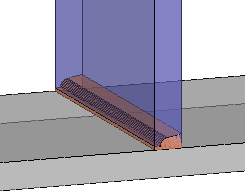

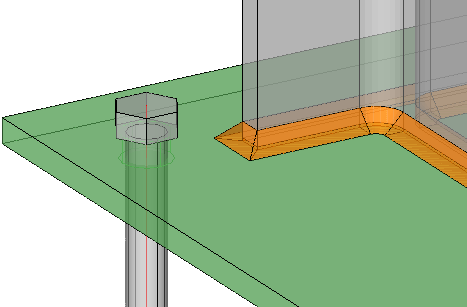

Welds

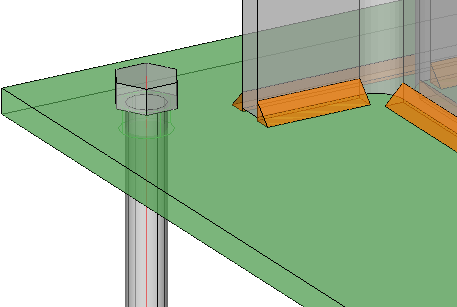

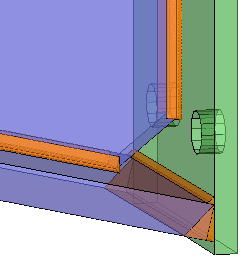

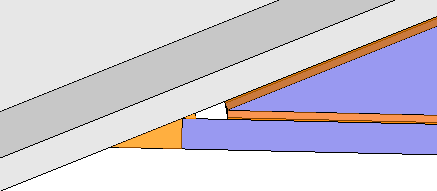

Parabuild allows you to model 3D welds for the most used structural weld types. There are several advantages to explicitly modeling welds. Visualization of welds will aid the user in determining problematic welding situations and wrongly sized welds. Weld symbols will be automatically added when generating shop drawings. Bills of material of a project’s welds can help with estimating, planning and scheduling of the welders. The 3D weld objects can also receive fabrication data and get a unique number for tracking purposes. In the near future we intend to extend these capabilities to include support for robotic welding.

A traditional hurdle with modeling welds is the amount of work involved for the detailer.

To make this go a lot faster we created the AutoWeld engine that can automatically create welds based on very flexible rulesets that the user can customize. Different weld types and sizes can be automatically assigned by a ruleset based on available model information like plate thickness, angle, structural types and much more. The standard Parabuild ruleset will create most structural welds automatically and can be used as the base for your own customized fabricator specific rulesets.

Further editing of the automatically created welds is then easily and quickly done using the properties panel or the weld editing dialog, making the overall process very efficient.

These are all the topics for the creation of welds and the automatic addition of weld symbols on the shop drawings :

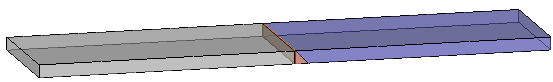

- The 3D Weld object

- It is possible to use the properties panel on the 3D Weld object. This topic also explains the purpose of each property.

- Automatically draw weld objects using AutoWeld

- Drawing welds with the context modeler

- Drawing welds from within the Macro dialog box

- Reviewing and modifying welds

- Deleting welds

- Removing weld segments

- Splitting / Merging welds

- Numbering welds

- There are settings in the shop drawings that will influence how the weld symbols are drawn and grouped on the 2D drawings.

See the Weld symbols on shop drawings topic for more information

Welding practices

If you need more general information about welding practices, we can refer you to the Structural Detailer site :

- Welding processes

- Joint types

- Fillet welds

- Weld preparations

- Basic weld symbols and an example weld for each

- ISO weld symbols